Products

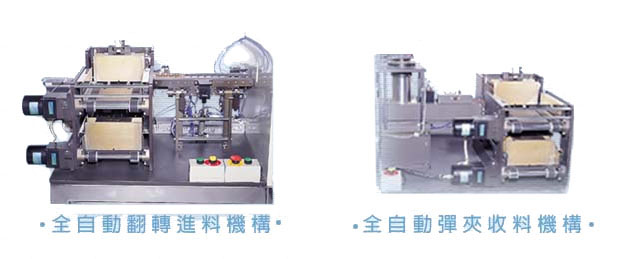

Auto Loader/Unloader

- 1. Normal production speed 600-1,000 SPH approximately.

- 2. Auto load/unload with two step-motor-driven elevator for non-stop magazine change over.

- 3. Elevator and suction arm operate by programmable step motor controller.

- 4. Intelligent one-touch elevator control system.

- 5. Standard side puch unloading can be replaced by optional connection with post-production.

- 6. Total more than 90 programmable timer for L/F jamproof.

- 7. Available pick & place by clamping-jaw, vacuum suction, magnetic attraction, gutter-clip pushing, separation, Available pick & place by clamping-jaw, vacuum suction, magnetic attraction, gutter-clip pushing, separation, etc. for load/unload.

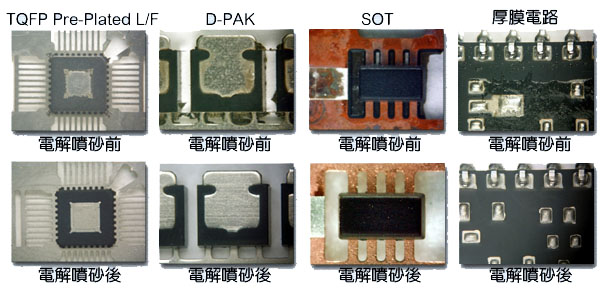

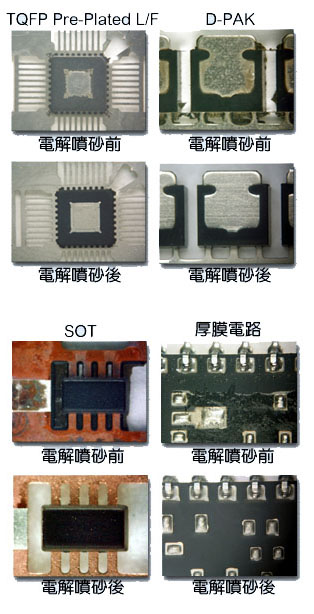

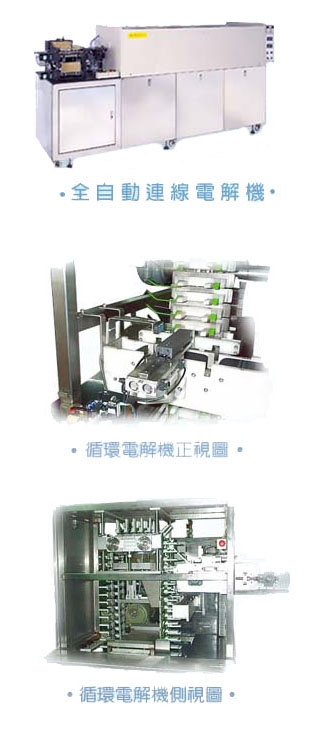

Stereocirculatory Electrolysis Deflash - The Most Sophisticated Model with Highest Capacity in the world

- 1. The smallest volume 1.4M(L)x1.4M(W)x2.0M(H) meter, the machine base is made by 304 rustless steel framework and acid-alkali cells, its great design is for easy-care and wheels for easy-move.

- 2. Its biggest managing capacity can contain 30-34 electrolysis cables contemporaneous.

- 3. The biggest load of electrolysis voltage current is 7VDC, 2-5A/each.

- 4. The longest time of circulating electrolysis is as 800 SPH, and lasts for 150 seconds.

- 5. The structure of circulating electrolysis made by rustless steel chains can be controlled the speed via digital frequency converter.

- 6. The electrolysis clamps made by 316 rustless steel body and spring (non-fragment style) can last longer and great conduction.

- 7. The electrolyte with patented circulating plastic-steel pump can filet impurities and objects efficiently.

- 8. The total capacity of electrolysis cell is 300 liters, and the negative plate is made by 316 rustless steel plate.

- 9. There are 10 lines of top-and-bottom circulating injections and one line of clean water on the scouring cell. This design can clean L/F efficiently.

- 10. The water usage can be controlled by screen-touching and by the parameter of cylindrical effusion meter. Its lowest rate can be 200-500 liter per hour.

Wet Blast Deflash - Design for Wafer, IC Assy, Thick Film and Magnesium

- 1. The usage of sand materials can save at least 50-100Kg per month, and suitable for 0.2-0.6mm resin-blast or thinner to other #800 mineral-sand materials. No static will produce. All products that had process of pre-electrolysis can proceed wet blast cleaning procedure and manufacture without drying.

- 2. The most fixable set of nozzles includes switches; the pressure controlled valve, the controlled paddle of gage pressure, and adjusting nozzle settings. Each nozzle turns on/off separately. That is for controlling every product dues to different effusion of glue by separately.

- 3. It is the real-time ultimate machine that bases on the track of materials feed-in/out and the motion part of wet blast cleaning washing. The track can contain the materials between 20 mm and 50mm thick and without adjusting the width of tracks.

- 4. 5 of each modern designed nozzle on the top and bottom, total are 10 nozzles. It divides into 10 sets of pressure-controlled-valve and works independently. After wet blast cleaning, there are 2-lines top-and-bottom to wash and 1-line top-and-bottom to dry.

- 5. The most convenient design can monitor the density of sand and water through the insert of transparent water tank, and supervise best condition of wet blast cleaning. During the process of manufacturing, the sand dust and glue remains would drain out; therefore, the product quality will be stable, because it can keep the sand materials inside of main water tank.

- 6. The fascinating design is waterproof of Chinese color-graphic-touching-screen, double level alarm and emergency stop bottom in the front and back.

- 7. The most water-saving design control by parameters of precipitation recycle system of three sand water tanks. The purpose of this design is using circulation to re-product sand water during washing and wet blast cleaning; touching-screen and parameter of cylindrical effusion meter can control the water usage. The lowest usage is 100 liters per hour.

- 8. The machine made by rustless steel body, which is rustless and durable. The windows of sand blasting chamber seals by aluminum air, it can effect to isolate the noise and sand water, furthermore, wash window automatically for easily observation and production.

- 9. Using separate motors control speed of feed-in/out materials and main driving sets of door rollers.

- 10. The best design of transmission is separating gear box that is drove by wet blast cleaning with blast chamber, and easy to maintain.

- 11. There are 4 rustless steel pumps in main water tank, precipitation, filter and washing tank. This special design can raise and stir sand water simultaneously.

- 12. For saving the usage of air pressure, it attaches the multiple cloud recycling-filter devices to dry by high-pressure air blower instead of high-pressure air.

- 13. The newly precipitation system of water recycling can reduce the density of sand water in main water tank, it can control the wet blast cleaning quality more efficiently.

- 14. Adding automatic maintain model can eliminate the gelatinous impurity of blast cleaning water tank automatically and efficiently centralize of and decrease of the sand materials at same time.

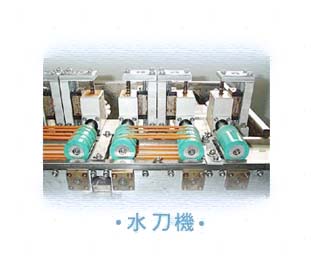

Water Jet Deflash - Ultrasonic Equipped

- 1. After wet blast cleaning, opt for high-pressured hydraulic bladder eliminating gelatin, within water washing and blow-drying.

- 2. The high-pressured pump can save most of energy that equals to 10Hp of air compressor and the water pressure can reach 500Kg/cm.

- 3. There are 4 nozzles each side of top and bottom. The effective range is 40-45mm.

- 4. The nozzle holders insert ultrasonic oscillators. That can increase the capability of eliminating gelatin of hydraulic bladder.

- 5. The isolating filtering system of water recycling includes recycling, precipitated run-out tank, filter, water tank. That will not only eliminate gelatin remains precisely but also save the usage of water and pump.

- 6. The water tank insert hydro-switch and Electro magnetic water-feeding valve, that can avoid water below alarm level.

- 7. The life of filter element of filter will monitor by microcomputer; its color screen-touching function will show every information in Chinese version and remind the supervisor to change the element.

- 8. The fixed plate board is easy to adjust the water pressure between the top and bottom separately.

- 9. The fine outlook design by two inserted high-pressured pumps.

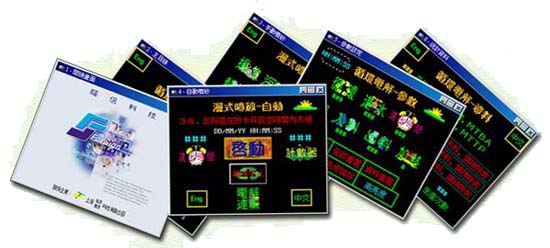

Control, Opertaion & Interface

- 1. The wet blast cleaning and circulating electrolysis are controlled by separate microcomputers, not only they own color screen-touching interfaces for each machine, but also connect to work together.

- 2. The color screen-touching interface includes both Chinese and English version and I/O numbers showing 3 ways to switch. The insert manuscript can indicate break information in Chinese and I/O number of break parts under auto-model, it is easy for trouble shutting.

- 3. There is anti-stuck sensor, which contains over 100 software of timers. It can trace every material when it processes to the electrolysis or blast cleaning on each line.

- 4. There has over 10 different production parameters can be set through screen-touching function, during the procedure period.

- 5. The insert device of censoring the power motor being over loaded can insure the quality of manufacture.

- 6. The materials of feeding in/out indicator can help workers to control the production.

- 7. The intelligent self-shutdown model can reduce the time of controllers, and make the device in the best condition of production.

- 8. Optional software of production analysis provides manufactures and engineers to well-understand the operating progress.

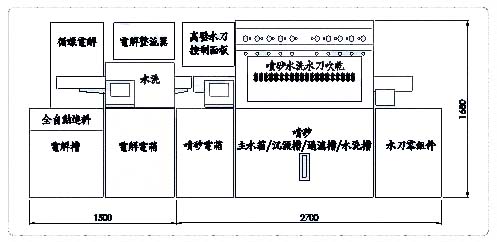

Equipment Outline

Including electrolysis: 4.2M(L) x 1.1M(W) x 1.8M(H)

Non-including electrolysis: 2.7M(L) x 0.8M(W) x 1.8M(H)

Materials

Electrolyte Introduction

Electrolyte (FX4-ECN) Properties

The most regular treatment of the remaining gelatin that produced during the process of semiconductor sealing are boiling-off exfoliation or electrolytic exfoliation for surface treatment of iron or non-iron materials. The kind chemists contain lots of acid-alkali materials and surface-active agent. The first one can not exfoliate the remaining gelatin, on the other hand, make gelatin solidification and harder to exfoliate. It also produces huge red precipitation when the electrolysis is processing, and attaches on objects. Moreover, the base's metal will be caustic embrittlement, because of contacting with alkali materials, and effect product durability. The surface-active agent will product lots of bubbles during the electrolysis. Besides above problems, there still have the problem of gelatin corrosion with bleaching and ashing simultaneously, and prints disappear too. The durability of acid-alkali exfoliation is very short and less than one week, no mater adding more exfoliation; it does not effect as the same and has to change new materials.

For resolving above problems, we start to research and analyze related studies, and receive the patent rights of some ingredients from oversea, to use in semiconductor-sealing manufactures in Taiwan. That is, Electrolytic remaining gelatin exfoliation (FX4-ECN) can control the concentration by visible efficiently.

FX4-ECN adapts special design of concentrated indicated agent. This design is mixed with electrolytic exfoliation smartly, and added appropriate moderator to keep the balance of density. In the practical process, we found the effect will consume by processing, but by adding FX4-ECN liquid to existing FX4-ECN. We can see the color changing from indigo back to transparent and non-precipitation, which means, the liquid has been rehabilitation and good for using. The reason is the electrolytic agent has aged when the color of FX4-ECN changes from transparent to indigo and some precipitation. Therefore, there is no need for daily use and manage of FX4-ECN by control of laboratory workers, but by senior supervisors. It can reduce the working load of operators.

Unique Characters :

| Item | Description |

| Outlook | Transparent or light-yellow liquid |

| PH Value | 12 |

| Flash point | non-ignite ability |

| Heavy metal | none |

| Halide | none |

| COD | 800-1,200 |

Maintenance

- -Level of electrolyte should below the base of heater, the full capacity of electrolytic cell is300L, the using capacity approximate 64*64*(74-14) / 1,000 = 245L.

- -Add pure water for supply, because of decreasing by evaporation and run-out.

- -Check the concentration of electrolyte daily and add in primary liquid when it is under level.

Analysis

- -Use a cone-bottle and leaving on electronic scale, and get approximate 3g liquid from cell, then record the weight precisely.

- -Add 100ml DI water.

- -Add few drops of Phenol red indicator.

- -Use 0.5N HCL titration, the end of titration is the liquid becomes to orange and record the consumption of HCL ml.

- -Count the concentration of electrolyte (%) =0.5N HCL consumption of titr ation ml *f* 14.61/weight of sample

- -The f is the titration compare of the master concentrated ratio of 0.5N HCL, if

basing on the master usage of 0.5N HCL, thenf=1, what if usage is 1N HCL, then

f=2.

Note: 14.61 is constant, do not change.

Calculation

- -For example: get 2.95g from electrolyte cell as sample, after adding 100ml DI water, the result of titration 0.5NHCL

- -The consumption is 5ml and total of electrolyte from electrolysis cell are 245L :

- -Count the using concentration (%) = 5*1*14.61/2.95 = 24.8%

- -Due to the using of master electrolyte is dilution by adding two-and-half times water then the primary liquid (100% concentrated), thus,The master concentration of electrolyte in using is 33.3%.

- -Primary liquid (100% concentrated) adding amount: total capacity of electrolyte * (標準master value - analysis value)= 245L*(33.3-24.8)/100 = 20.825L

- -Based on the result, only add 20.825L primary electrolyte, then can make 245L, the in using electrolyte of 24.8% concentrated liquid to the concentration rate to 33.3%.

Material Safety Data Sheet - Electrolyte Fox-301

I. Product & manufacture information

- Product name : Electrolysis exfoliation

- Serial number : FOX-301

- Manufacture/supplier : Foxsign Tech. Ltd. Co.

- Registration number : 868-10649

- Address : No. 500-1, Sec. 2, Jinling Rd., Pingjen City, Taoyuan,Taiwan

- Telephone number : (886)3-459-3304 , 458-0873

- Emergent ontact/Fax : (886)3-458-0873

II. Ingredient information

- Chinese/English: 電解去膠劑 / FOX-301

- Synonym : None

- Chemistry Association Society registration number (CAS N0): 1310-58-3

- Dangerous ingredient (percentage): 20%

- Chemistry Property : Basic Liquid

III. Dangerous identification information

- Strenuous danger effect : the stimulation by basic liquid

- Major Symptoms : stimulate respiratory system and skin, or cause

- burn when it is eriously : 3

IV. Emergent procedure by different exploration

- By Breath:move to flesh air place, or give CPR if not having breath and send to hospital immediately.

- By skin contact :wash by clean water at least 5 minutes.

- By Eye contact :hold eyelids wide open and wash by clean water at least 5 minutes, and send to hospital immediately

- By mouth :do not force to vomit and urge to hospital.

- The strenuous symptoms and effects :stimulation, or cause burn when it is seriously.

- Protection for Emergent staffs :avoid direct contact.

- Instruction for Doctor :contact with basic liquid of KOH

V. Procedure for extinguishing Fire

- Fire extinguishing materials:non-combustibility, no need for using fire extinguisher

- Other danger to extinguish fire :none

- Special procedure for extinguishing fire:none

VI. Procedure for leaking

- Personal notice : avoid directly contact

- Notice of environment : keep well ventilation, avoid leaking continuously

- Cleaning procedure : spray with huge water or neutralize with light acid.

VII. Safety & storage instruction

- Handle :clear instruction on the container

- Storage :store at cool, dry and airflow well place. Avoid exploring under the sun directly.

VIII. Protection of exploration

- Instruct control : keep airflow well in the working place, set exhaust system separately.

- Parameter control : keep over 1,000 litters/per mints of air drafting above cell.

- Personal protection gear : working shoes, emergent shower and eye wash equipment.

- Breath protection : the protection equipment with cleaning strainer or oxygen self-provide.

- Hand protection : protect gloves

- Eyes protection : Goggles and mask.

- Skin & body protection : avoid contact directly

- Hygienic arrangement : ventilation

IX. Physics & chemist property

- Material condition :stable

- Shape :Liquid

- Color :transparent-light yellow

- Odor :distinguish smell

- PH value: 13.5

- Boiling point :100 - 110°C

- Deposing temperature :none

- Flash point : none

- Temperature of self-ignition :none

- Explore limitation :none

- Steam pressure gauge :none

- Density of steam :none

- Density : 1.2 +/- 0.05

- Desolution :totally

X. Stability & reaction

- Stability :highly stable liquid.

- Possible dangerous reaction in special situation :stimulation, cause serious burn.

- Avoiding situation :avoid contacting with acid-material

- Avoiding materials :none

- Dangerous deposition :none

XI.Toxic information

- Vigorous toxic : none

- Portion reaction : none

- Sensible reaction : stimulus

- Chronic toxic : none

- Special reaction : none

XII. Ecology information

- Possible influence of environment :it is harmful for the living when concentration raises.

XIII. Deposition treatment

- Deposition treatment :add acid materials to moderate and dilute and drain.

XIV. Transportation information

- International transportation regulation : none

- United nation serial number : none

- Internal transportation regulation : none

- Special notice for transportation : using bucket to avoid leaking

XV. Regulation information

- Regulation : none

XVI. Other information

- Reference : none

- Present by : Foxsign Tech Ltd. Co.

- Prepared by : 李素琴

- Prepared date : 2001.1.31

Material Safety Data Sheet - Plastic Blast Media,Fox Series

BRANDNAME

FoxSign FOX Plast TYP A

REVISION DATE Dec 28, 2001

1. MATERIAL-/ PREPARATION AND COMPANY NAME

| PRODUCT DETAILS | FoxSign FOX Plast |

| PRODUCER DETAILS | FoxSign Technology, Corp.No 500-1, Gin-Lin 2nd Rd, Peng-Zeng City, Tao-Yuan,Taiwan, R.O.C. |

| EMERGENSY TEL | TEL 886-3-458-0873 TEL 886-3-459-3304 |

2. CONSTITUTION / COMPONENT DATA

| CHEMICAL CHARACTERISTICS | AMINOPLAST SHAPING MASS HARDENED |

| DESCRIPTION | PLASTICS PRODUCED FROM URIN RESIN, CARBANIDE RESIN OR MELANINE RESIN |

| DANGEROS COMPONENTS IN THEPRODUCT | NOT APPLICABLE |

| CONTENS IN % | NOT APPLICABLE |

| R-INDEX | NOT APPLICABLE |

| CAS-NUMBER | NOT APPLICABLE |

| EINECS-NUMBER | NOT APPLICABLE |

| OTHER COMPONENTS | PLASTICS PRODUCED FROM URIN RESIN, CARBAMIDE RESIN OR MELAMINE RESIN |

3. POSSIBLE DANGERS

| DESCRIBTION OF DANGERS | NO HEALTH DAMAGING DANGERS IN HARDEN PRODUCTS |

| SPECIAL DANGER FOR MEN AMD ENVIRONMENT | NO ENVIRONMENTALLY DAMAGING PROPERTIES, AS THE MATERIAL IS INACTIVE AND BIOLOGICALLY DIFFICULT TO DECOMPOSE |

4. FIRST AID MEASURES

| GENERELL INSTRUCTIONS | IN CASE OF SYMTOMS OR IN CASE OF DOUBT SEEK A DOCTOR |

| AMD ENVIRONMENT | FRESH AIR PUT AFFLICTED PERSONS IN THE RECOVERY POSITION IF BREATHING IS IRREGULAR OR BREATHING HAS STOPPED, PERSON RESPIRATION AND ARRANGE IMMEDIALTY FOR FURTHER TREATMENT MEDICAL |

| AFTER SWALLOWING | ON SWALLOWING CONSULT A DOCTOR IMMEDIATLY. |

| AFTER CONTACT WITH EYES | RINSE THUROUGHLY WITH WATER IF IRRITATION PERSISTS, SEEK A DOCTOR. |

| AFTER SKIN CONTACTS | WASH THE AFFECTED SKIN WITH WATER. |

5. MEASURES OF FIRE FIGHTING

| SUITABLE EXTINGUISHING SUBSTANCE | FOAM, C02, POWDER, WATER(H20) |

| PARTICULAR DANGER FROM | INHALATING OF DANGEROUS |

| MATERIAL, ITS COMBUSSION | DECOMPOSITION PRODUCTS CAN |

| SPECIAL PROTECTIVE EQUIPMENT | PROTECTIVE BREATHING DEVICE,IF NECCESSARY |

6. MEASURES ON UNINTENSIONAL RELEASE

| PERSON RELATED | KEEP CLEAR FROM SOURCES OF |

| PROTECTION MEASURES | IGNITION AND PREVENT COLLECTING OF DUST. MATERIAL LEFT LAYING AROUND CAN INCREASE DANGER |

| ENVIRONMENTAL PROTECTION | NO ENVIRONMENTAL DAMAGES PROPERTIES, AS MATERIAL INACTIVE AND DIFFICULT TO BIOLOGICALLY DECOMPOSE. |

| PROCEDURES FOR CLEANING UP | MATERIAL LEET LAYING AROUND SHOULD BE PICKED MECHANICALLY. |

7. HANDLING AND STORAGE

| GENERAL INSTRUCTIONS | STORE DRY. DO NOT USE OR |

| FOR SAFE USE | STORE PRODUCT IN PROXIMITY OF NAKED FLAMES, HEAT OR IGNITION SOURCES. |

| INSTRUCTIONS FOR FIRE AND EXPLOSION PROTECTION | REMOVE EXISTING DUST BY CLEANING |

| STORAGE TEMPERATURE (C) | SURROUNDING TEMPERATURE |

| STORAGE CLASS | NOT APPLICABLE |

8. LIMITS OF EXPOSURE AND PERSONAL PROTECTIVE EQUIPMENT

| EXPOSURE LIMITS AT | DO NOT APLFLY FOR THE HARDEN |

| PLACE OF WORK | PRODUCT. |

| MAX CONCENTRATION | 6 mg/m3 FINE DUST CONCENTRATION |

| PERSONAL PROTECTIVE EQUIPMENT | PROTECTIVE BREATHING MASK PROTECTIVE GOGGLES |

9. PHYSICAL AND CHEMICAL PROPERITIES

| FORM | SOLID (GRANULATE) |

| STANDARD - GRAI | FINE 0.2 - 0.6mm MIDDLE 0.6 - 1.0mm ROUGH 1.0 - 1.6mm |

| SPECIAL - GRAIN | FINE 0.2 - 0.5mm MIDDLE 0.5 - 0.8mm ROUGH 0.8 - 1.2mm |

| PCOLOR | MULTI - COLORED |

| SMELL | NOT APPLICABLE |

| PH - VALUE | NOT APPLICABLE |

| CHANGE OF STATE | NOT APPLICABLE |

| BOILING POINT / RANGE | NOT APPLICABLE |

| MELTING POINT / RANGE | NOT APPLICABLE |

| FLAMABLE POIN | NOT APPLICABLE |

| IGNITION TEMP ( C ) | APPROX 350 C |

| DENSITY 20 C | 1.5 g/cm3 |

| DENSITY 20 C | APPROX 900 Kg/m3 |

| LOWER EXPLOSION LIMIT | 130 g/m3 |

| UPPER EXPLOSION LIMIT | NOT APPLICABLE |

| SELF IGNITION | NOT APPLICABLE |

| SOLUBICITY | NOT APPLICABLE |

| VISCOSITY | NOT APPLICABLE |

| FURTHER DETAILS | NOT APPLICABLE |

NAME

| PRODUCT | FoxSign |

| PRODUCT | FoxSign |

| PRODUCT | FoxSign |

10. STABILITY AND REACTIVITY

| STABILITY | STABLE |

| CONDITIONS TO AVOID | NOT APPLICABLE |

| CHANGE OF STATE | NONE, IF USED PROPERLY A THERMAL DECOMPOSITION STARTS AT 450 C, THIS CAN LEAD TO DANGEROUS RELEASE PRODUCTS, E.G. SMOKE. CO . CO2 |

11. DATA REGARDING TOXICOLOGY

| ACUTE TOXICILOGY | NONE |

| SPECIAL SYMTOMS IN ANIMAL TESTING | NOT APPLICABLE |

| SENSIIVITY SUBACUTB OR CHRONIC | NOT APPLICABLE |

| TOXICITY | NONE |

| FURTHER DETAILS | NO FURTHER DETAILS APPLICABLE |

12. ECO LOCIGAL DATA

| ECO TOXIC EFFECTS | NO ENVIRONMENTAL DAMAGE PROPERTIES, AS MATERIAL INACTIVE AND DIFFICULT TO BIOLOGICALLY DECOMPOSE. |

13. INSTRUCTIONS FOR DISPOSAL

| THE INFORMATION BELOW APPLIES TO THE PRODUCT AS IT IS AND NOT TO FURTHER PROCCESSED PRODUCTS. OTHER DISPOSAL METHODS MAYBE REQUIRED , IF MIXED WITH OTHER PRODUCTS OR MATERIALS. | |

| DISPOSAL CODE NUMBER LAGA | 57107 HARDENED SHAPED SANDS |

| DISPOSAL CODE NUMBER EWC | 120105 PLASTIC PARTS |

14. TRANSPORT DATA

| GROUND TRANSPORT ADR/RID GGVS/GGVE | NOT A DANGEROUS PRODUCT |

| CLASS, DIGIT, I.D.LETTER | NOT APPLICABLE |

| SENSIIVITY SUBACUTB OR CHRONIC | NOT APPLICABLE |

| DANGER ID - NUMBER | NOT APPLICABLE |

| DANGER SHEET SAMPLE NO | NOT APPLICABLE |

| ACCIDENT SHEET NO | NOT APPLICABLE |

| INLAND SEA TRANSPORT ADN/ADNR | NOT A DANGEROUS PRODUCT |

| CLASS, DIGIT, I.D.LETTER | NOT APPLICABLE |

| DANGER SHEET - NO | NOT APPLICABLE |

| AVIATION - TRANSPORT ICAO/IATA - CLASS | NOT A DANGEROUS PRODUCT |

| PACKAGING REGULATIONS | NOT APPLICABLE |

15. REGULATIONS

| IDENTIFICATION | NOT REQUIRED |

| CLASSIFICATION ACC.TO VBF | NOT REQUIRED |

| SENSIIVITY SUBACUTB OR CHRONIC | NOT REQUIRED |

| TA - AIR | NOT REQUIRED |

| WGK | 0 |

16. FURTHER DETAILS

THE DETAILS CONTAINED HERE IN ONLY REFER TO THE NAMEND PRODUCT. THEY CAN HOWEVER NO LONGER APPLY IF THE PRODUCT IS USED WITH OTHER MATERIALS OR IN OTHER PRODUCTION PROCESSES. THE STATEMENTS ARE IN ACCORDANCE WITH OUR KNOWLEDGE AND EXPERIENCE AT THE GIVEN

DATE. HOWEVER NO LIABILITY FOR FAULTIENESS. RELIABILITY AND COMPLETENESS WILL BE GIVEN. THE USER MUST CONVINCE HIMSELF THAT ALL STATEMENTS FOR HIS INDIVIDUAL USE ARE SUITABLE AND COMPLETE.

Our clients

Contact us

- Factory Address : No. 20, Lane 193, Lane 148, Qingwen Road, Xinwu District, Taoyuan, Taiwan

- Company Address : 9Fl., No. 13, Shinfu 3rd St., Pingjen City, Taoyuan, Taiwan

- E-Mail : foxsign@ms34.hinet.net

- Tel:(886)3-459-3304 / (886)3-458-0873

- Fax:(886)3-459-3305